Automatic Granule Snack Food/Rice/Beans/Seeds/Sugar/Peanut/Grain/Potato Chips/Nuts/Popcorn Sachet Packer

Working Processes :

Feeding--Conveying--Weighting--Forming ( Filling--Sealing ) --Finish Products

Product intruction

Apply for the packaging of medical supplies, food, hardware and other particle in bulk such as electuary, spices,sugar, coffee,seeds and monosodium glutamate .

1,Stainless steel surrounds the part where contact to the material. The machine is accordant with the European CE standard.

2,The computer controller is the first patented product in China, an advanced frequency converter, and supports multi-language control.

3,Rolled disc cup adjusting device can adjust packaging capacity during running the machine, reduce the lostof material and improve productivity.

4,Bag-making equipment can be changed according to specific requirement of customers and products so as to adjust the amount of packaging.

5,Multi-language touch screen can switch various languages at the same time, and when there is a problem with the machine, it will automatically alarm, pause the operation and show where the machine is in the problem.

6,Screw metering,Kitech exclusive patented technology device, using a new straight screw metering weighing, when the packaging weight is not accurate will automatically adjust to reach the preset weight, no manual operation to adjust, saving time and cost.

7,Double Scale Weighing Device,Kitech's exclusive patented technology device,Secondary weighing and testing of the finished packaging products, when the packaging weight is not accurate, it will automatically reject the unqualified products and feed back to the measuring cup metering device system for automatic adjustment of the entire weight, which will increase the qualified rate products to 100%.

8,Servo control system is used on machine weighing device, film pulling device, bag making and sealing. When there is a problem in one part, the machine will automatically stop running and alarm to remind the operator to check, therefore, one person can operate 15 machines at the same time to save cost.

Automatic granule packaging machine features: 1.Automatic granule packing machine can finish the process like conveying bag,bag making,filling,weighing,sealing,cutting,counting,lot number,etc. 2.Bilingual display screen control system,stainless steel cabinet.Set up the required data(include filling,weighing,bag size,etc) in the visuable settings,the control system automatic optimization match with all the program so that achieve the best packing speed precisely. 3.Stepper Motor control,this system has the advantage of precise,needless to adjust the other parts. 4.It has color system controller,so that can get the complete trade mark design. 5.Suitable for the complex film and tin foil and other packing material.Fine packaging performance,low noise,clear sealing texture and strong sealing performance. 6.Mitsubishi PLC control,customize details according customer's requirement Technical Parameters

| Machine model | BG-160ZS | BG-100ZS |

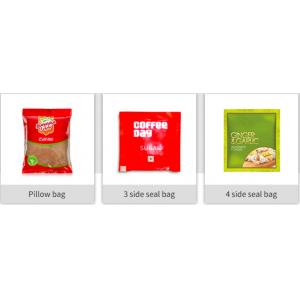

| Bag shape | pillow bag/stick sachet/3 side sealing/4 side sealing |

| Packing speed | 10-70bags/min | 10-60bags/min |

| packing capacity | 1-300g | 1-50g |

| Roll thickness | 0.05-0.15mm |

| Roll diameter | Max:300mm |

| Roll width | 30-320mm | 30-240mm |

| Bag width | 50-150mm | 30-100mm |

| Bag length | 40-200mm | 30-150mm |

| Powder | 220V/50HZ/1.2KW | 220V/50HZ/1.4KW |

| Additonal configuration | Coding printer/Gas-filled device/Bag connecting device/punch device/Easy to tear gap device |

Please tell us about your bag size and we can match the suitable machine for you.

Scope of application:

Granule Packing Machine is suitable for pharmacy,food,household chemicals,plastic products and other special industry and other loose type and granule material. Such as seeds,Chinese Drugs, feeding stuff,medicinal granules,salt,sugar,soup blend,oat,tea,active carbon,washing powder,etc.

Machine features:

1. This machine can automatically complete following work: material lifting--volumetric cup/multi-head weighter measuring--coding--bag making--filling--gas injection/exhaust (optional)--sealing--counting-- conveying finished products--sorting finished products.

2. Imported PLC servo and pneumatic control system and super touch screen to form the drive control center; high reliability and the intellectualized degree, and equipped with safety protection.

3. Touch screen can store a variety of different product packaging process parameters when replacement product can be used at any time without having to reset.

4. Equipped with fault display system, when the fault occurs, be clear at a glance, in order to promptly eliminate it.

5. Can make hole punching device after customer's request.

6. All the contact materials parts are stainless steel 304.

Technical parameters

| Item | Sprcification |

| Measuring range | 10G~5KG |

| Film width | 50~260mm/50~240mm |

| Bag length | 50~180mm |

| Bag width | 50~120mm |

| Appearance | Stainless steel 304 |

| Bag type | Back seal bag/side seal bag |

| Speed | 25~60bags/min |

| Power | 220V,50-60Hz,1.2kw |

| Weight | L1000×W700×H1650mm |